Proud of their water purifier are Mr. and Mrs. Gerald L. Didier as they point to part of the water system that they have installed on their homestead on the Yuma Mesa Division, Gila project. The system includes the water softener to Mr. Didier's right, the germicidal lamp purifier in the middle, and the automatic water heater to Mrs. Didier's left. Photo by M. N. Langley of the bureau's Region 3.

Proud of their water purifier are Mr. and Mrs. Gerald L. Didier as they point to part of the water system that they have installed on their homestead on the Yuma Mesa Division, Gila project. The system includes the water softener to Mr. Didier's right, the germicidal lamp purifier in the middle, and the automatic water heater to Mrs. Didier's left. Photo by M. N. Langley of the bureau's Region 3.Water in the Yuma Mesa irrigation ditches starts out high in the Rocky Mountains as pure rain or snow. It flows down the Colorado River into Lake Mead, above Hoover Dam, then is released to downstream areas, stopping briefly in the reservoirs behind Davis, Parker, Headgate Rock, and Imperial Dams. From Imperial Dam, it is diverted into the Gila Gravity Main Canal and is lifted upon the mesa by huge pumps, then, through a lined distribution system, it flows to some 6l,840 acres under irrigation, 4,940 acres of which made up the Bureau's 1940 land opening.

Along the approximately 1,400-mile descent from the Rockies to the Yuma Mesa, the water loses some of its purity, at least to the point where it is not considered safe for drinking until the bacteria that may cause typhoid, dysentery, or other dangerous diseases has been removed.

Some of the homesteaders are solving their problems with the technical advice of Reclamation Engineer Joseph P. Collopy, operation and maintenance supervisor for the Lower Colorado River district, and his staff. They run the water through sand filters, then treat it with germicidal lamps.

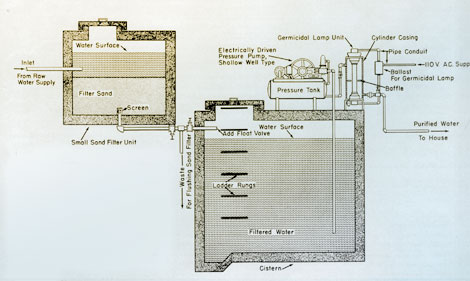

The "Violet Ray" treatment devised at Yuma Mesa. The diagram shows the pipe entering about three-quarters of the way up the cylinder casing. In Didier's purifier, water rises around lamp, is circulated by several baffles and leaves through outlet pipe seen near top on front of unit. In diagram, outlet pipe is shown near bottom of right-hand side of lamp unit. The illustration on this page is based upon shop drawings for the construction of purifying unit made at the district manager's office of the Lower Colorado River District, Yuma, Ariz. District Manager M. J. Miller states they have not yet attempted to make refinements in design that would be desirable if such units were to be manufactured in quantities. Illustration prepared by Bureau's Graphics Section in Washington, D.C., based on Region 3 drawing.

The "Violet Ray" treatment devised at Yuma Mesa. The diagram shows the pipe entering about three-quarters of the way up the cylinder casing. In Didier's purifier, water rises around lamp, is circulated by several baffles and leaves through outlet pipe seen near top on front of unit. In diagram, outlet pipe is shown near bottom of right-hand side of lamp unit. The illustration on this page is based upon shop drawings for the construction of purifying unit made at the district manager's office of the Lower Colorado River District, Yuma, Ariz. District Manager M. J. Miller states they have not yet attempted to make refinements in design that would be desirable if such units were to be manufactured in quantities. Illustration prepared by Bureau's Graphics Section in Washington, D.C., based on Region 3 drawing.Chlorinators are usually regarded as standard equipment for water supply systems of any size. Although effective and dependable, they require some skilled supervision and prove expensive when one is needed for each user, as on irrigation projects.

Results of the first installation, which was in the Yuma Mesa pumping plant building, were quite satisfactory. The Thomas Laboratories, a commercial firm in Yuma, tested the water before and after the ultraviolet ray treatment. In its raw state, the water carried a heavy count of bacteria of the Coli-Aerogenes group which causes typhoid and dysentery. After water passed through the purifier, the biological tests showed, without exception, that these bacteria were not present.

It is roughly estimated that 300 gallons can be purified per hour by a 15-watt unit. All installations are checked by frequent biological analysis, especially those that are operated near the estimated full capacity. The units have been operating quite satisfactorily for over 2 years. Mr. Collopy cautioned farmers on other projects who are considering similar installations to consult first with public health or other qualified authorities, as factors in other locations may be different.

Source: The Reclamation ERA, December 1950

For more information:

http://www.usbr.gov/projects/Project.jsp?proj_Name=Gila+Project

View large image

View large image