You are viewing ARCHIVED content published online before January 20, 2025. Please note that this content is NOT UPDATED, and links may not work. For current information, visit https://www.usbr.gov

Crews at Glen Canyon Dam and Powerplant fix a leaking penstock

Repairing a leaking penstock is a little like fixing a leak under your sink, except that a leaking penstock is a much, much bigger job and one that the maintenance crew at Glen Canyon Dam had never faced until recently.

Engineers discovered the leak during a routine inspection in August, and determined it was coming from both expansion joints on one of the penstocks. Glen Canyon Dam has eight penstocks that convey water from Lake Powell to the powerplant’s turbines. Each penstock has two expansion joints—the first expansion joint is located roughly 400 feet from where the water enters the face of the dam and the second one is about 75 feet farther downstream. Both are housed in separate vaults measuring approximately 24 feet long by 24 feet wide by 20 feet high to provide access to the joints for regular inspections and repairs. The expansion joints provide flexibility to take the brunt of the water’s force.

Crews started work on the project in February, which is an ideal time to make a repair like this because “there’s less water coming through the powerplant because there’s less demand for power,” explained Glen Canyon Dam Maintenance Supervisor Ray Ripka.

Both a maintenance crew and a mechanical crew, made up of five personnel each, worked on the repairs, which involved removing and replacing the packing material inside both expansion joints. The packing material is a compressible material that, when the penstock’s flange and collar are bolted back together, creates a water-tight seal to guard against leaks.

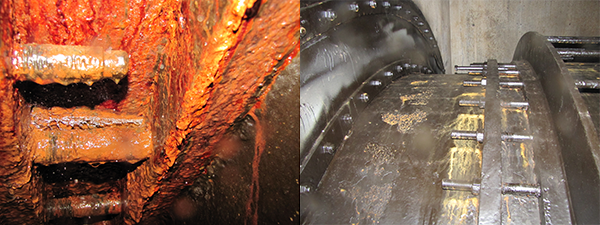

Before crews could get to work, they had to turn off the water supply. To do that, they dropped the penstock’s gate to let water drain out of the 15-foot-wide pipe and to prevent more water from coming in. The maintenance crew then removed the layers of rust and slime that had built up on the outside of the penstock because of the leaks.

Next, the mechanical crew removed the 67 bolts around the joint’s flanges. They then used hydraulic jacks and come-along pulls to carefully and slowly pull the penstock’s collar away from the flange.

“This was tricky because we had to pull the collar back evenly all the way around the 15-foot-wide penstock. The penstock is made of stainless steel, which doesn’t slide easily, and there’s only about 1/8-inch clearance around it,” said Ripka. “I believe this is the first time the pieces had been pulled apart since the dam was constructed.”

After the pipe was pulled apart, crews got to work on another tedious task: removing the old packing material. After more than 60 years, the original packing material had become brittle, allowing water to get through.

“It wasn’t easy to remove,” said Ripka. “It had to be pulled out little by little and piece by piece using a variety of tools that we could reach in there and get it out.”

With the old packing removed, it was time to put in the new material. Crews squeezed in six layers of packing material in the tight space between the penstock and the flange. They alternated between a flexible packing material and rubber, and ensured the seams never aligned for added security.

With the new packing material in place, it was time to put the expansion joint back together. Crews slowly moved the collar back in place and tightened the flange’s 67 bolts little by little in an incremental pattern to keep the collar straight and ensure it evenly compressed against the new packing material to create a tight seal.

Crews made the same repairs on the second expansion joint and when they were finished, they lifted the gate and reintroduced water into the penstock. A small leak was found, but after the bolts were tightened a bit more, the leak stopped.

Regular inspections and maintenance, as well as making needed repairs like this, have helped keep the dam in good shape since it started impounding water in March 1963 and the powerplant running efficiently since it first generated electricity in September 1964.