Two Reclamation facilities more than 1,100 miles apart come together for a first-time project

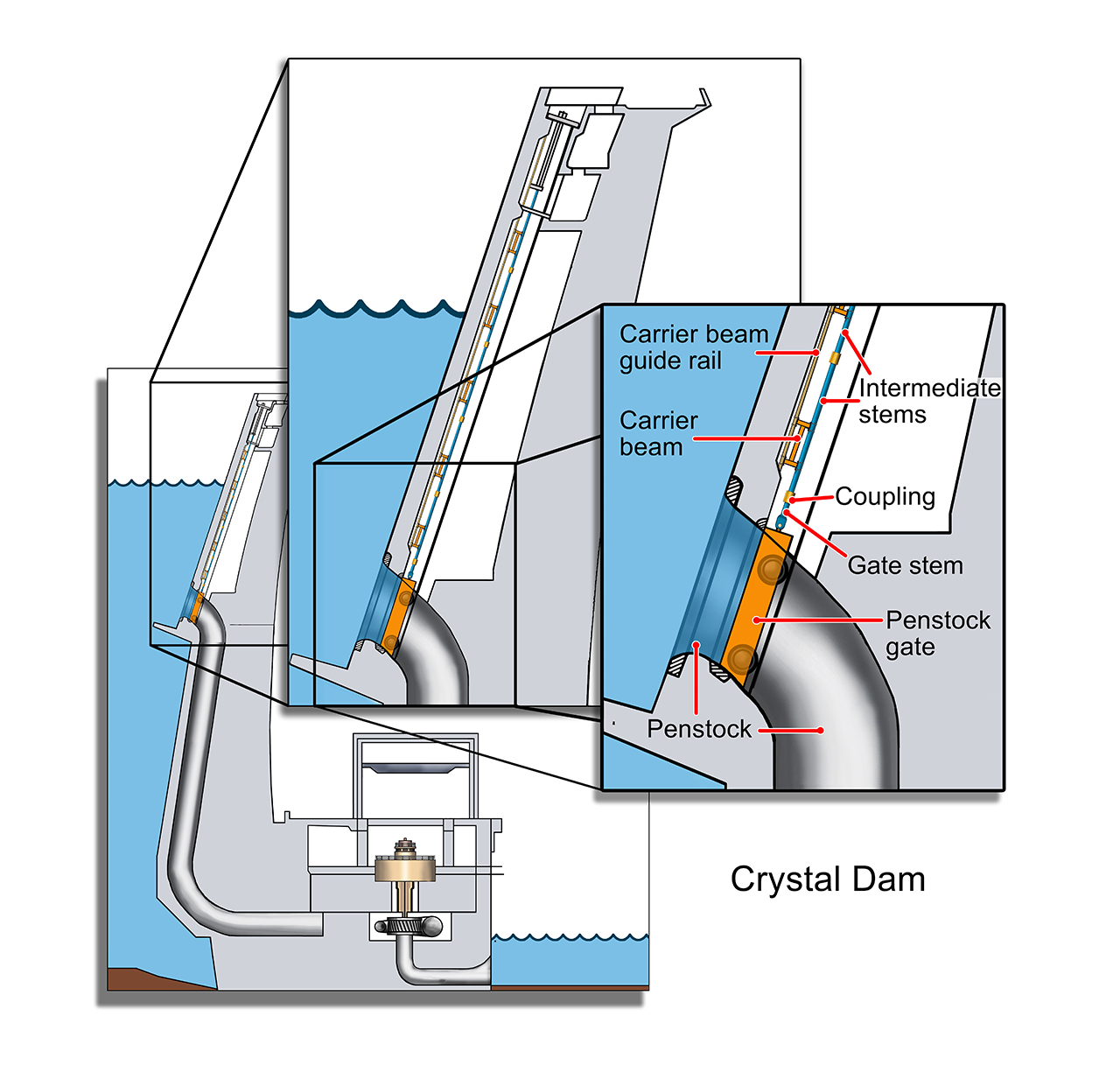

During an annual inspection of the fixed wheel gate at Crystal Dam, Reclamation engineers recommended that the parts that do the heavy lifting – the gate stems, carrier beams and couplings – should be recoated. But after further discussion, it was decided to replace the parts because of their poor condition.

Crystal mechanics could manufacture the carrier beams, but the gate stems and couplings would have to be made elsewhere.

For a job that complex, Crystal personnel looked to one of the biggest dams and powerplants in the country, Grand Coulee Dam and Powerplant in Reclamation’s Columbia-Pacific Northwest Region in Washington state.

“Our former mechanic, Jared Foran, had the idea to ask the machinists at Grand Coulee if they could manufacture the pieces. He had previously served a four-year apprenticeship there and knew what kind of equipment they had and what they were capable of,” shared Grant Watson, Plant Supervisor for Crystal.

Crystal and Grand Coulee worked out the details of the job and the raw material was procured: four pieces of round stock measuring 5 inches in diameter and 16 feet long to make the intermediate stems, and one piece of round stock measuring 7 inches in diameter and 16 feet long to make the gate stem and five couplings. The material was shipped to Grand Coulee in November 2020, but because of COVID-19 and a backlog of projects that piled up while employees safely stayed home, it was July 2021 when Grand Coulee machinists started working on Crystal’s parts.

“It’s amazing what they did,” said Justin Miller, Grand Coulee’s Machine Shop Supervisor, reflecting back on his team’s work. “To start with that raw material—solid carbon steel—and turn it down into those pieces was something to see.”

The intermediate stems are made up of four 16-foot-long pieces held together by couplings. At the top, it is connected to a hydraulic lift, and at the bottom, it is connected to the 8’x13’ fixed-wheel gate that, when closed, prevents water from the reservoir from going into the penstock and through the hydropower turbine.

Crystal Dam maintenance worker and equipment operator Spencer Esch drove more than 2,200 miles roundtrip to pick up the new gate stems and couplings from Crystal Dam, located 6 miles downstream from Morrow Point Dam on the Gunnison River, approximately 20 miles east of Montrose, Colorado, to Grand Coulee Dam, located on the Columbia River west of Spokane, Washington.

Esch said the trip was well worth it, providing an opportunity to “meet people, build relationships, see what they’re doing, and what we can share with them.”

After pickup, the gate and intermediate stems were coated and all of the new parts will be installed at Crystal Dam later this year. Watson said that even though COVID-19 delayed the project, working with Grand Coulee to manufacture the gate stem and couplings still saved time and money and is “a good example of the regions working together for the good of Reclamation as a whole. I never stop being impressed at the talented people in Reclamation.”